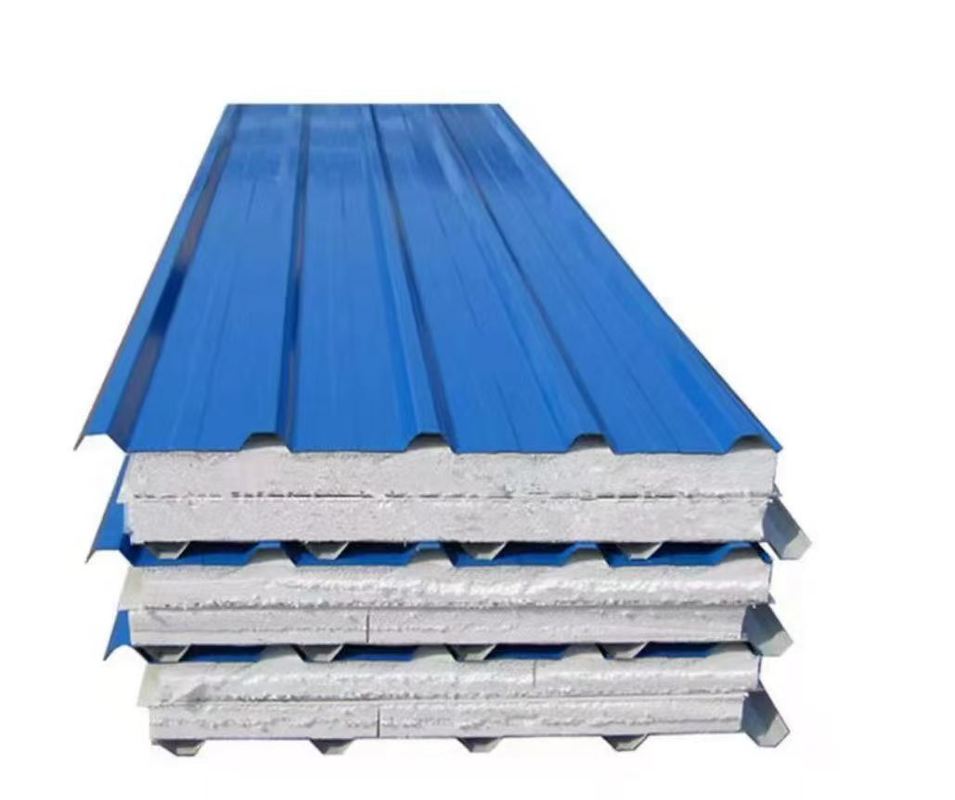

The Sandwich Panel Roll Forming Machine is a key equipment in the production line for EPS sandwich panels, commonly used in the manufacturing of sandwich roof panels and wall panels. This machine is designed to efficiently produce high-quality sandwich panels with precision and speed.

One of the standout features of this Sandwich Panel Roll Forming Machine is its roller material. The rollers are made of Cr12, a durable material known for its strength and longevity. This ensures smooth and consistent forming of the sandwich panels, resulting in a uniform product.

Equipped with blades made of Cr12 with heat treatment, this machine is capable of effectively cutting the sandwich panels to the desired thickness. The material thickness range of 50-300 allows for versatility in production, meeting various requirements for different applications.

The cutting mode of the Sandwich Panel Roll Forming Machine is hydraulic guide column, which offers precision cutting and efficient operation. This cutting mechanism ensures clean and accurate cuts, contributing to the overall quality of the sandwich panels produced.

For seamless operation and control, this machine is integrated with a PLC control system. The PLC control system provides automated control over the entire production process, allowing for easy adjustments and monitoring of key parameters. This enhances efficiency and productivity in the production of sandwich panels.

In summary, the Sandwich Panel Roll Forming Machine is an essential component of any sandwich panel production line. With its robust construction, advanced features, and precise control system, this machine enables the efficient and accurate manufacturing of sandwich roof panels and wall panels.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!